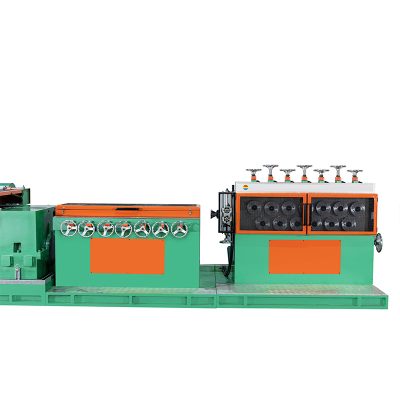

The combined drawing unit is special equipment for producing cold-drawn bars with different shapes and specifications. It is a combined unit that integrates the processes of uncoiling, initial straightening,drawing and fine straightening, cutting to length, polishing and collection of finished products.

LBJZ continuous drawing unit is high precision and high efficiency professional processing equipment of metal rod and pipe. The unit has functions of uncoiling, initial straightening, stretching, fine straightening, cutting to length, feeding, polishing and finished products collection etc. It integrates multiple processes and can process a variety of special-shaped materials, such as hexagonal, square, flat square and round shapes as well as other varieties of profiles.

LHJZ-6

1. Maximum pulling force: 60kn

2. Rated drawing speed: 5-60 m/min step-less speed regulation

3. Processing materials and diameter:45#Steel Round Material ∅6mm-∅16mm

4. Processing length: 2-6m (±5mm)

5. Finished product surface roughness: Ra0.4um- Ra 0.8um

6. Finished product straightness: bars≤0.5mm/m

7. Product outer diameter tolerance: ±0.01mm

8. Total unit power: 155 KW

9. Main motor power: 90KW

10. Main power: Three-phase 380V/ 50 HZ

11. Air Pressure: 6kg/cm2 ±1kg/ cm2

12. Approximate total weight of unit: 25T

13. Approximate Dimensions: 28M*2M*1.3M

Equipment Configuration

A1. Control cabinet

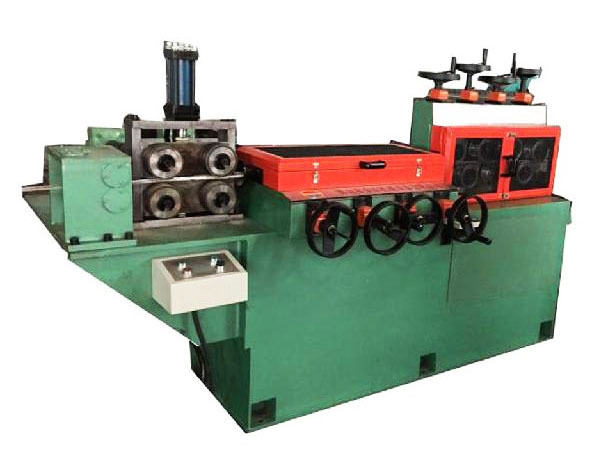

A2. Pay off rack, initial straightening machine

A3. Main drawing machine

A4. Fine straightening system

A5. Hydraulic shearing machine

A6. Guiding rack

A7. Polishing unit, collecting device